Critical Need for New Pipelines

Oil production in the Permian Basin has passed 4 million barrels a day, but because of pipeline constraints, it’s selling at a discount. Transport bottlenecks are also to blame for low natural gas prices, resulting in reduced production and flaring of 661 million cubic feet per day – an all-time high. The pressure on pipelines to solve the industry’s price and production woes is enormous. But in the post-downturn era, capital projects have smaller budgets – even the critical ones. For pipeline construction firms, the expectation is to do more with less.

Ten years ago, controlling costs was not a major concern of the O&G industry. High oil prices meant big budgets with plenty of room for overages. The oil price free-fall that began in 2014 changed everything. By 2016, an estimated $380 billion in projects had been cancelled worldwide as firms shifted into survival mode.

The downturn left its mark on the industry and today, even in the booming Permian Basin, things are done differently. In the most productive oil field in the world, drilling companies have leveraged technology to drive down break-even costs from over $60 a barrel to as low as $33. E&P companies in the region have curbed spending and now focus on increasing cash flows as a primary objective.

New efficiencies in the upstream sector have set a precedent, but pipeline construction isn’t well-positioned to slash break-even numbers like drilling has. Pipelines are safer than ever, but one critical leak flows unabated: the profit lost during construction.

Financial Integrity Dig – Finding the Deficiency

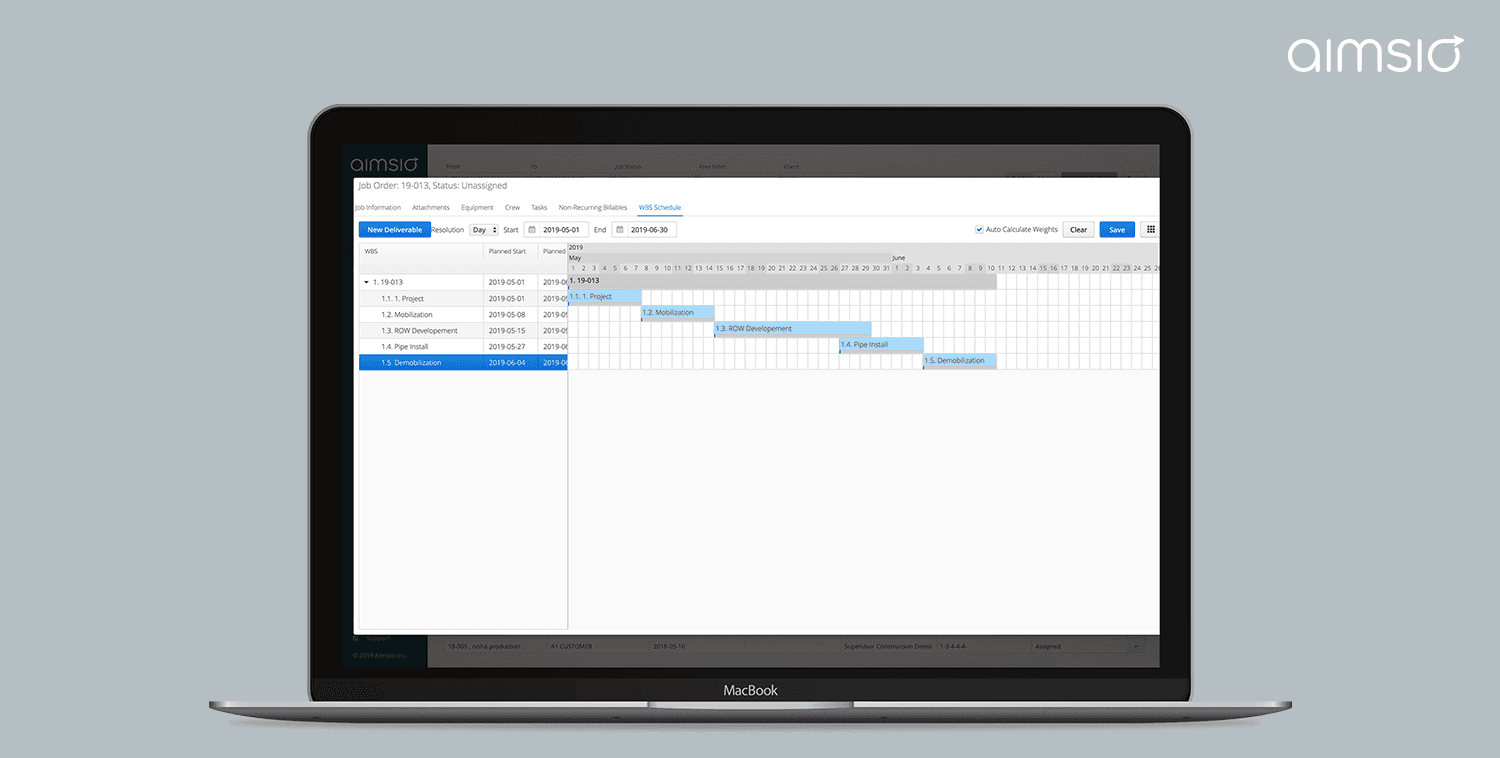

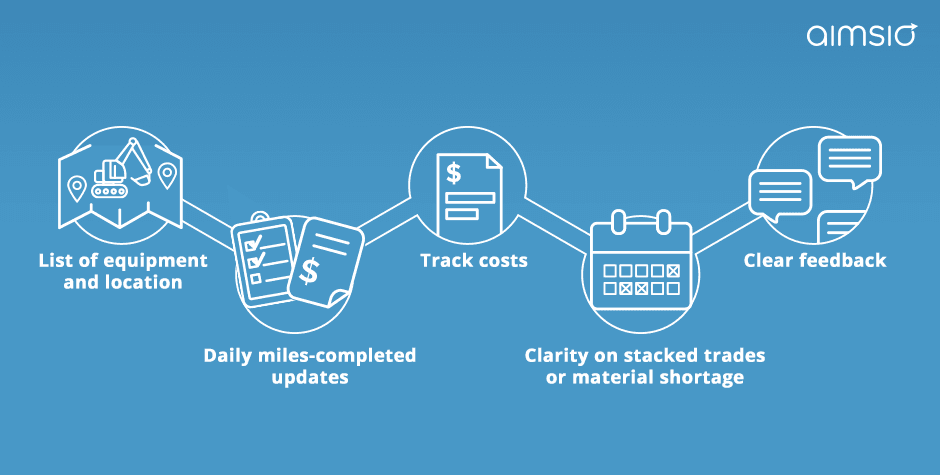

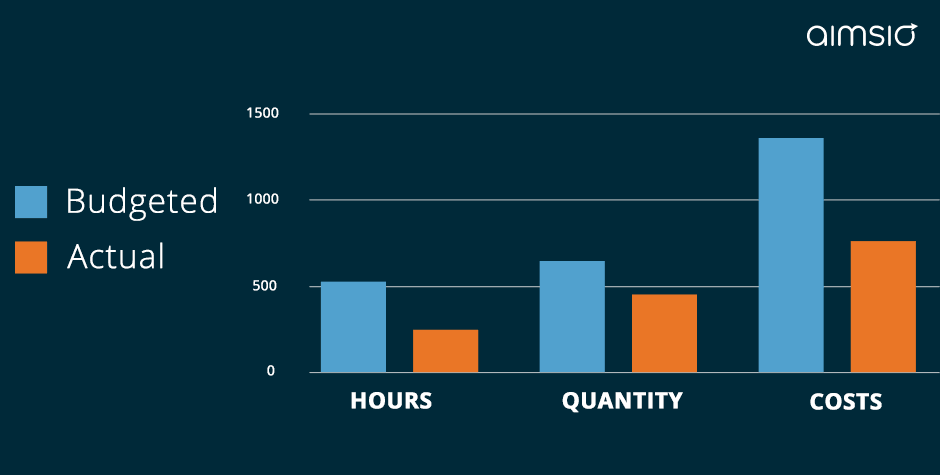

The simple answer to increasing profits is to reduce costs and get control over billing — fast. This means daily updates of critical KPIs in order to effectively manage a lean construction on the right of way. Increased visibility of day-to-day operations is imperative. Activities in the field should be recorded quickly and accurately. And they should be accessible from a reliable “single source of truth” to eliminate communication breakdowns between the office and field.

If you’re using paper tickets and spreadsheets, you already know what’s wrong with the old way of doing things. Paper copies from the field come late, get lost, or aren’t filled out right. Entering data is incredibly time consuming. It’s also another chance for mistakes to be made, leading to bad numbers being used by operations and finance. Getting ahead of your costs is tough when lost paper and disconnected spreadsheets have you playing catch-up.

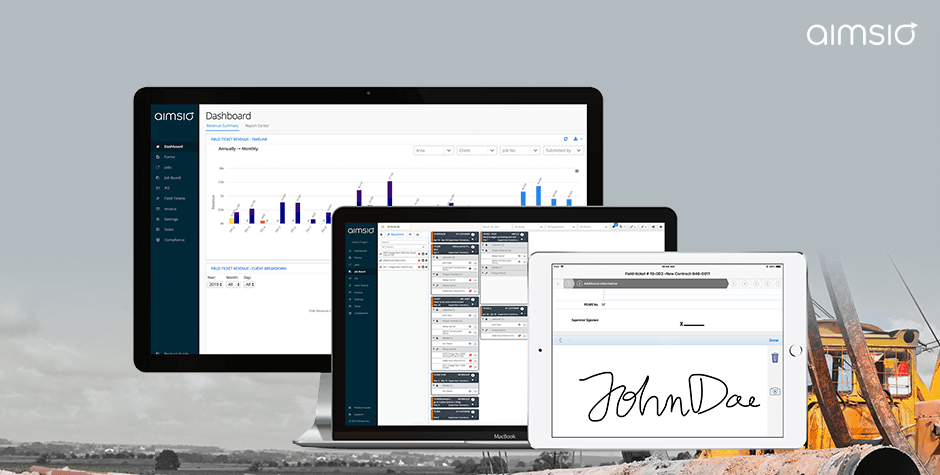

The Solution: Ditch the paper

Digitization – the conversion of information to digital format – improves managerial, operational and financial processes by creating a link between the office and the right of way. Clarity and communication flows both ways allowing for efficient processing of POs, change orders, and payroll. Reporting, compliance, asset management and billing is completely transformed when data can be accessed daily from desktop or mobile device. Cloud storage means client turnover packages are quickly assembled and past projects are easily referenced for bidding or integrity requirements.

A digital link to the ROW can give you daily access to:

- a complete inventory and location of equipment

- site progress reports

- inspector reports

- employee timesheets

- subcontractor invoices

- equipment maintenance reports

- material tracking

How much money could be made if you had this level of visibility into your field activities?

At Aimsio, we’ve seen the impact digitizing field operations has on the bottom line. We understand the complexities of pipeline construction and tailor our modules for your unique operations.