The answer is yes.

For early adopters, AI is already helping businesses. According to independent research firm McKinsey Global Institute, 2016 saw businesses invest an estimated $39 billion worldwide in AI technology. Even though the report states that “artificial intelligence is poised to unleash the next wave of digital disruption”, it found the majority of leaders surveyed are uncertain of how AI fits their business case and if return on investment would be realized.

While many stakeholders have heard buzzword-packed statements about the potential of AI to disrupt and innovate, uncertainty still remains. Higher profit margins are enticing, but where does AI fit in the equation?

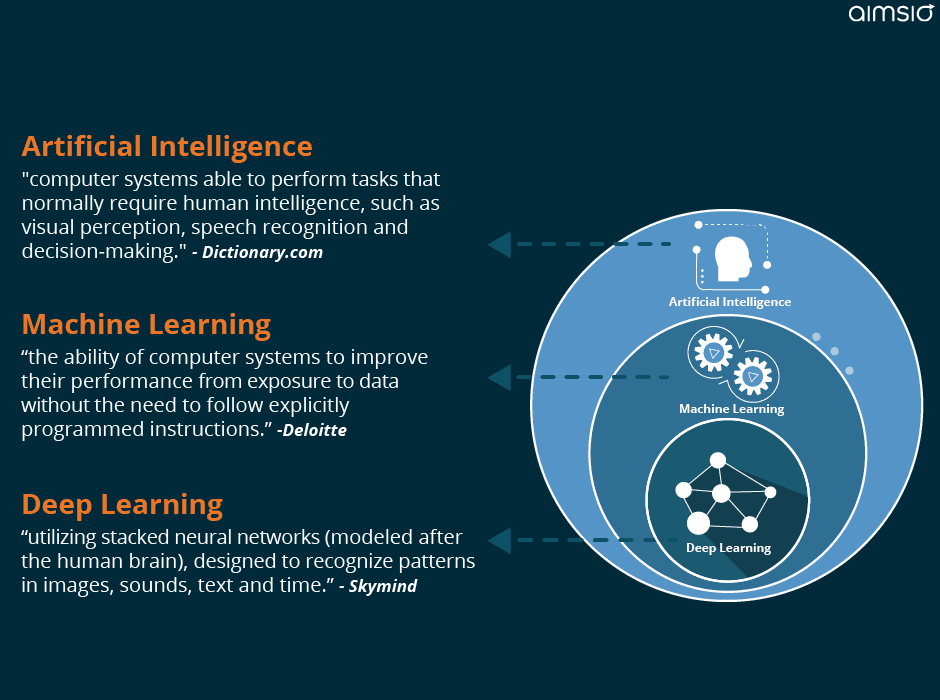

Before we get to that, let’s unpack the jargon we need to understand the technology.

Artificial intelligence describes computer algorithms that have human characteristics such as the ability to reason, problem-solve and learn. An algorithm is simply a sequence of instructions that tell a computer how to complete a task. Machine learning is a way of achieving AI without manually coding the instructions. Instead, a machine learning algorithm is fed large amounts of data and adjusts itself to find improvements. Companies like Uber use machine learning to convert the vast amounts of data collected from the app into optimized routes and improved user experiences.

Some early industrial of AI can be found in the transportation and manufacturing industries. Machine learning is allowing digital-savvy companies in these sectors improve operations and increase profits through route optimization and intelligent automation.

1. Route Optimization

Efficiency for delivery companies is heavily affected by two precious commodities, time and fuel. UPS spent ten years and over $100 million on an algorithm that plans the most cost-effective route for drivers who make an average of 120 stops each day.

AI also helps smaller delivery companies. Startup Routific created an algorithm inspired by the way that bees share the best routes to their food sources with other bees. Used by companies like DoorDash, Routific can save up to 40 per cent on driving time and fuel.

2. Intelligent automation

GE has more than 500 manufacturing facilities around the world that make everything from toaster ovens to jet engines. In 2015, they built their first “Brilliant Factory”, powered by Predix, an Internet of Things (IoT) platform with powerful deep learning capabilities. After a $1 billion investment, GE has seen positive improvements at the AI-powered factories such as a decrease in unplanned downtime, increased productivity and an improvement in on-time delivery rates.

Since field operations are Aimsio’s specialty, let’s look at how artificial intelligence benefits companies that have remote crews and equipment to manage.

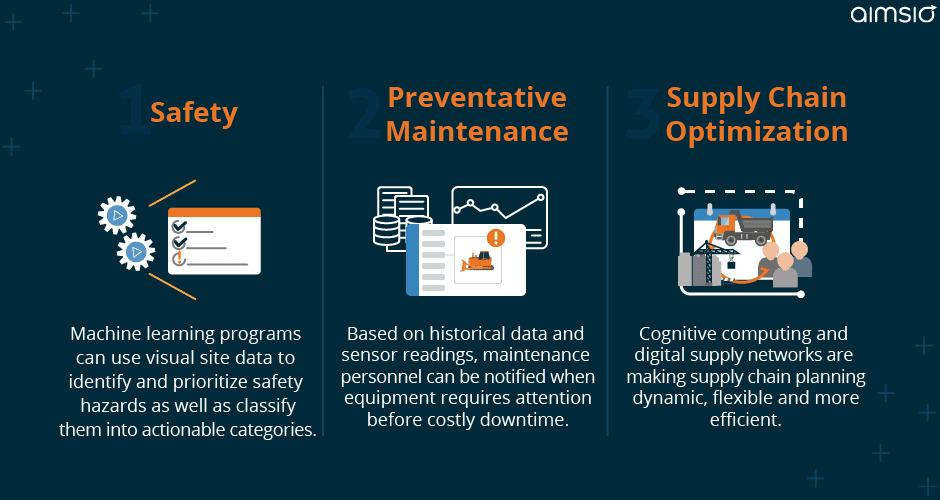

Safety

Machine learning has vastly improved the ability of computers to recognize images. Platforms such as Smartvid.io’s VINNIE (Very Intelligent Neural Network for Insight and Evaluation) process large quantities of images and video from construction sites at high speed. We’re talking more than 1000 images in less than 10 minutes. The files are sorted and tagged according to any potential hazards identified, as well as non-compliance issues such as missing PPE.

Users configure the system to send alerts to HSE administrators where further investigation and mitigation is carried out. For companies with multiple remote sites to manage, this level of efficiency offers a safer work environment without extra HSE administrators.

Predictive Maintenance

AI can be also leveraged by high-capital industries such as heavy construction, and oil and gas to minimize equipment downtime and maintenance costs. Large firms are already utilizing the IoT to monitor assets, but the vast amounts of data accumulated can be further analyzed to produce valuable insights.

Machine learning programs use historical data and sensor readings to anticipate equipment failures and initiate an automated service request at the optimal time. This is sometimes referred to as “self-maintenance” and is considered the future of AI for asset management.

Supply Chain Optimization

The nature of project planning is shifting as linear supply chains evolve into interconnected digital supply networks. Full integration of all aspects of the business, along with constant flow of data through a network of vendors and suppliers allows for synchronized planning. This enables organizations to plan production with agility and speed, increasing both margins and client satisfaction.

Is your business ready for AI?

A clear strategy is the first step to integrating AI; with a distinct problem to solve, a targeted AI solution can be developed. David Goff, head of Enterprise Networks at Cisco UK & Ireland believes, “with networks powered by AI and machine-learning, the workplace becomes less tangled up in complexity and repetition, and more agile as a result.” In order for the benefits to be realized, Goff stresses that “organizations and their decision-makers need to ensure that the technology solution is addressing a problem or gap”.

The next step is to ensure that sufficient data in the right format is available. Data must be consolidated across platforms and cleaned-up in order to be utilized. Aimsio Co-founder Abbas Sarraf, PhD in Machine Learning, estimates two-to-three years of data is required for machine learning to produce valuable predictions, depending on the application. For instance, an algorithm to optimize mobilization and demob procedures can be developed, but in order for machine learning to predict the optimal route, details of previous efficient and inefficient mobs must be compared. A machine learning algorithm analyzes all available variables and learns what factors impact the cost of moving equipment, producing the most economical option.

However, potential roadblocks to successful AI integration do exist. Information Age, a publication for CTOs, identifies two integration challenges that should be considered. First, the global digital skills shortage will create a bottleneck for companies seeking AI integration. Implementing a retraining, recruitment and retention program ahead of the technology could prevent service interruption. Legacy systems pose additional issues. Many large enterprises are based on aging, customized platforms that make integrating new technology challenging. Stakeholders that forecast intelligent automation and machine learning systems as the future of their operations can be well prepared by addressing these issues.

At Aimsio, we’re looking forward to the positive impact AI will have on the industries we service. In the meantime, we’re already brainstorming ways to integrate AI into our platform in order to solve our clients’ unique challenges. If you are wondering how AI could be integrated in your business, we can help you see the possibilities. Click the link to connect with us.