But, to be eligible to work on lucrative projects, companies must be willing to jump through a few hoops. Furthermore, working for multiple clients often calls for prequalification from multiple contractor management companies, as well as learning and implementing separate invoicing systems and paying a slew of subscriptions. The ROI becomes challenging to identify – there is no bonus for the extra input; the time and money spent is simply a pay-to-play cost.

Prequalification

The introduction of third-party contractor management companies was meant to create a standardized method of assessing and comparing pipeline construction firms, streamlining the process of awarding contracts for the big midstream players. But, as many contractors are aware, an array of management companies emerged and continue to persist in the market. The responsibility of remaining compliant with multiple vendors falls to contractors and results in redundant uploads, submissions and subscriptions. Too bad hoop jumping doesn’t burn calories.  Keeping up with the demands of remaining compliant has become a full-time endeavour and is carried out in addition to a company’s functional safety program. Once awarded a contract, it’s safety business as usual: client expectations regarding the customization and administration of a safety program remain, including vetting and managing subcontractors.

Keeping up with the demands of remaining compliant has become a full-time endeavour and is carried out in addition to a company’s functional safety program. Once awarded a contract, it’s safety business as usual: client expectations regarding the customization and administration of a safety program remain, including vetting and managing subcontractors.

Where the trouble begins:

ISNetworld®, PICS® (now Avetta®), PEC, ComplyWorks, ContractorCheck, COR™, CQN – the list is an alphabet soup of acronyms representing a multitude of service providers all striving to be the premier contractor prequalification partner. Thanks to the free market, they each occupy enough overlapping space to impact a pipeline construction company’s ability to manage and administer their HSE programs. While many contractors are familiar with obtaining the safety certification specific to their provincial or state requirements, a predicament arises when multiple clients require different assessments from different prequalification partners. If, for example, a pipeline construction company is bidding on projects for three potential clients concurrently, there is a strong possibility that prequalification with three separate firms will be required. The increased workload of applying to (and remaining compliant with) each prequalification partner is significant, straining department resources and requiring additional personnel.

How did the pipeline industry get heine debate ofre?

It appears prequalification requirements may originate with Canada’s pipeline tribunal, the National Energy Board. The NEB is Canada’s independent federal regulator (a Young Guns reference was successfully resisted here) which has been mandated to “promote safety and security, environmental protection and efficient energy infrastructure and markets in the Canadian public interest.” Pipelines and transmission lines that cross provincial or national boundaries fall under their jurisdiction, as well as oil and gas exploration, drilling, export of oil, natural gas imports, pipeline tolls and tariffs – the list is extensive. The need for an independent energy regulator became apparent during a particularly acrimonious period in Canadian politics. The pipeline debate of 1956 involved such intense inter-party feuding and public embroilment that it effectively ended the Liberal government’s 20 year tenure. On the consequent recommendation of two separate commissions, the NEB was created to ensure that the Canadian energy sector could operate free from political encumbrance.  Speaking of encumbrance, this is where the dots connect: for numerous projects, the NEB mandates that ISNetworld® is used to carry out the “contractor competency evaluation process. The list of prime contractors regulated by the NEB (and therefore required to comply with process requests) includes virtually every energy infrastructure company with assets in Canada. If you cross a border, any border, you’re invited to the party. Contractors that plan to bid on a project regulated by the NEB will not successfully prequalify until their questionnaire, safety program, insurance, and OSHA/WCB certification have been reviewed, assessed and assigned a grade by ISN®. Not so bad – one and done, right? Not necessarily. A phone call to the ISN® customer service line confirmed that while the primary ISNetworld® questionnaire contained one to two thousand questions (no joke), each hiring client can require additional questionnaires and customize the type documents to be uploaded by each contractor. Also, on projects not regulated by the NEB, clients can choose any of the other service providers, such as ComplyWorks. It’s not uncommon for smaller contractors to require extra, part-time staff solely to manage compliance requirements. As one consultant notes, “the big producers like to do things their own way and that means the little guys have to run to keep up to multiple systems.”

Speaking of encumbrance, this is where the dots connect: for numerous projects, the NEB mandates that ISNetworld® is used to carry out the “contractor competency evaluation process. The list of prime contractors regulated by the NEB (and therefore required to comply with process requests) includes virtually every energy infrastructure company with assets in Canada. If you cross a border, any border, you’re invited to the party. Contractors that plan to bid on a project regulated by the NEB will not successfully prequalify until their questionnaire, safety program, insurance, and OSHA/WCB certification have been reviewed, assessed and assigned a grade by ISN®. Not so bad – one and done, right? Not necessarily. A phone call to the ISN® customer service line confirmed that while the primary ISNetworld® questionnaire contained one to two thousand questions (no joke), each hiring client can require additional questionnaires and customize the type documents to be uploaded by each contractor. Also, on projects not regulated by the NEB, clients can choose any of the other service providers, such as ComplyWorks. It’s not uncommon for smaller contractors to require extra, part-time staff solely to manage compliance requirements. As one consultant notes, “the big producers like to do things their own way and that means the little guys have to run to keep up to multiple systems.”

With regard to multiple systems, compliance isn’t the only area where clients request the use of particular platforms.

Invoicing Systems

Besides prequalification requirements, big companies are able to stipulate that contractors submit invoices using specific accounting software. It definitely seems reasonable for a company that receives 5000 invoices a month to streamline the process, saving time and money. But what does this look like for contractors? It could mean entering information into Open Invoice, Ariba®, and/or Cortex, as well as an in-house system for internal accounting. These additional demands on an accounting department become truly overwhelming if invoices from subcontractors are arriving in a coffee-stained stack of handwritten, generic invoices torn out of a book.  The time spent deciphering and reconciling accounts payable can be frustrating and begs the question: “Isn’t there a better way to do this?”. While the burden of flexibility seems to fall solely onto the prime contractor, examining the management of subcontractors may uncover efficiencies which allow pipeline construction companies to remain profitable as client expectations increase.

The time spent deciphering and reconciling accounts payable can be frustrating and begs the question: “Isn’t there a better way to do this?”. While the burden of flexibility seems to fall solely onto the prime contractor, examining the management of subcontractors may uncover efficiencies which allow pipeline construction companies to remain profitable as client expectations increase.

The Good News

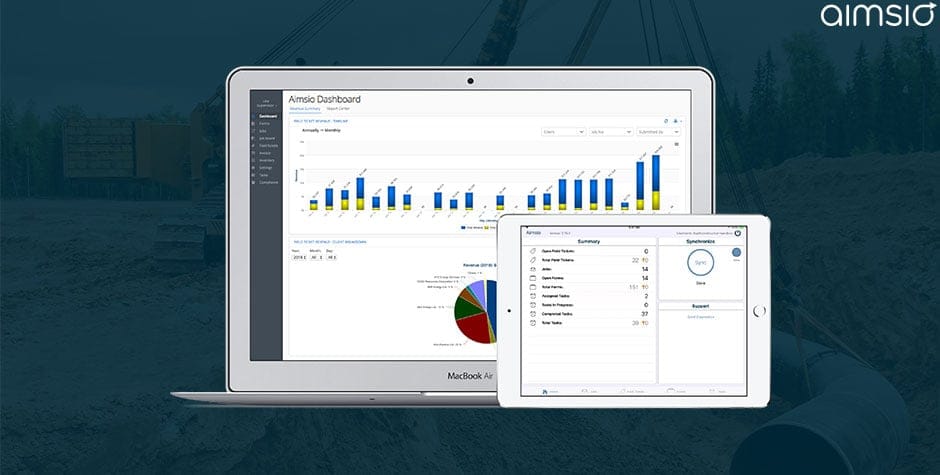

Well, first the bad news: clients are big and they do what they want. Multiple contractor management systems and invoicing requirements are likely to continue to be the hurdles and hoops contractors need to jump through, leap over, shimmy under – even when it would be oh-so-gratifying to walk over them with a D10. One way to lessen the negative impact is to offset the increased inputs associated with client stipulations by implementing lean management strategies elsewhere in your operation. Successful lean initiatives improve operating margins by “driving out inefficiencies, reducing costs and waste, increasing value and decreasing variability” Ready for the good news? It appears that while so far internal digital management systems have been under-utilized by the construction industry as a whole, digitization can create profound efficiencies that allow administrative focus to shift to the demands of managing special client requirements.  For example, by implementing a paperless safety tailgate form, numerous processes are eliminated. A physical stack of forms no longer needs to be copied and sent out to the field with foremen. Filling out paperwork becomes a series of auto-populated fields and menu selections. Back at the office, submitting, collecting, filing and retrieving tailgates can be done electronically with a few clicks. A digitized safety system can make contractor prequalification easier as well. When it’s time to apply, rather than manually sorting through files and scanning documents, files can be electronically selected and uploaded. The time and effort spent managing subs can be significantly reduced, too. By forwarding digitized replicas of a standard invoice, subcontractors are able to fill the forms out on a device and submit electronically. This way, the contractor receives all vendor invoices in a clear, consistent format and the subcontractor simplifies their own invoicing process at the same time. In terms of subcontractor safety program management, digital compliance records can ensure field verification checks by the client go smoothly. Imagine if all required tickets, certificates, waivers and information for your workers and subcontractors could be accessed on your laptop or handheld device. Inspections become fast and simple, allowing the foreman’s focus to get back to production.

For example, by implementing a paperless safety tailgate form, numerous processes are eliminated. A physical stack of forms no longer needs to be copied and sent out to the field with foremen. Filling out paperwork becomes a series of auto-populated fields and menu selections. Back at the office, submitting, collecting, filing and retrieving tailgates can be done electronically with a few clicks. A digitized safety system can make contractor prequalification easier as well. When it’s time to apply, rather than manually sorting through files and scanning documents, files can be electronically selected and uploaded. The time and effort spent managing subs can be significantly reduced, too. By forwarding digitized replicas of a standard invoice, subcontractors are able to fill the forms out on a device and submit electronically. This way, the contractor receives all vendor invoices in a clear, consistent format and the subcontractor simplifies their own invoicing process at the same time. In terms of subcontractor safety program management, digital compliance records can ensure field verification checks by the client go smoothly. Imagine if all required tickets, certificates, waivers and information for your workers and subcontractors could be accessed on your laptop or handheld device. Inspections become fast and simple, allowing the foreman’s focus to get back to production.

Choosing the right platform is critical in order for digital implementation to have the greatest positive impact on the pursuit of lean pipeline construction. The best way to streamline field operations management is to select and all-in-one platform that is able to capture every process in the production cycle from bidding to dispatching, internal reporting, safety and compliance. When everything is integrated within the same system, information can be accessed, shared and utilized efficiently. The bottom line is, before hiring additional staff to successfully accommodate client requests, take advantage of an all-in-one digital platform that can consolidate the management of your field operations.